Motorbike labelling debated

|

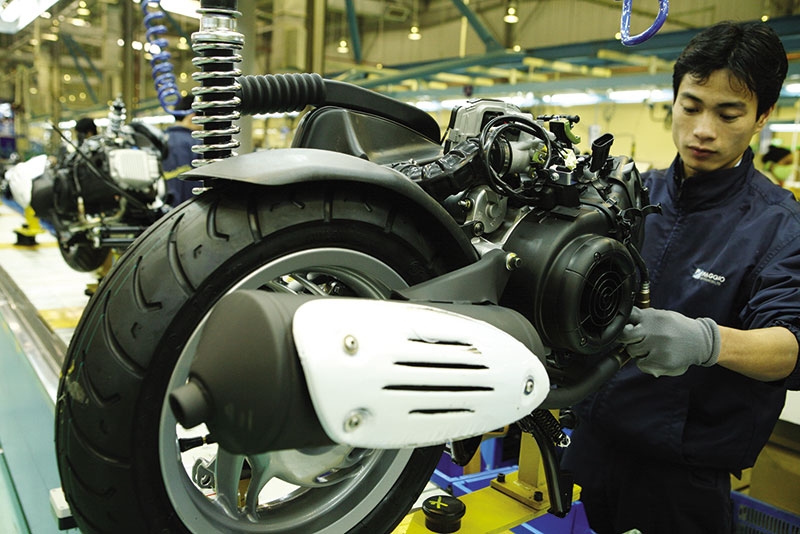

| Industry representatives think that it is unnecessary to put energy efficiency labels on motorbikes, photo Le Toan |

Under the draft circular on energy labelling, the labelling scheme for motorcycles is voluntary until December 31, 2019 and will be compulsory after that. The plan aims to provide consumers with necessary information to weigh before purchasing such bikes and to encourage manufacturers to further innovate technology to market the most energy-efficient products.

The Vietnam Association of Motorcycle Manufacturers said that labelling was an unnecessary measure, especially with the limited capacity and resources available in Vietnam, as all information is already provided to customers. The association is now collecting comments from its members to submit to the Ministry of Transport.

A representative of a leading foreign motorcycle maker in Vietnam, who declined to be named, told VIR that specifications such as fuel consumption have been provided in the manual given to buyers, so printing the energy specifications on the stamp is quite simple.

“The management agency needs to check and confirm how and when the testing is carried out, and whether the stamp is for a new model,” she said.

Huynh Kim Tuoc, director of the Ho Chi Minh City Energy Conservation Centre, questioned whether the measure was really to meet the regulators’ green goals or to create more bureaucratic paperwork for firms.

Two years ago, the Ministry of Industry and Trade (MoIT) released Circular No.36/2016/TT-BCT on energy labelling for devices and equipment using energy, replacing Circular No.07/2012/TT-BCT in order to cut administrative procedures. The move made life easier for thousands of local manufacturers and foreign importers, while still meeting all firms’ expectations.

Under Circular 07 enacted in April 2012, to certify energy labelling and minimum energy proficiency standards (MEPS), manufacturers and importers must have product samples tested at laboratories appointed by MoIT. According to the circular, labels must show test results issued by the appointed testing organisations within a period not exceeding six months from the date of issue.

Under current regulations, before being marketed in Vietnam, thousands of products, such as refrigerators, printers, and light bulbs, have to be tested for MEPS and obtain an energy label.

Firms complained that the insufficient number of eligible testing centres in the country has prolonged testing times and raised costs for enterprises. Currently, there are only six authorised testing centres across the country, and each one is only eligible to test a certain group of products.

The American Chamber of Commerce in Vietnam suggested that the MEPS requirement on certification by an accredited domestic test centre should be waived for well-known global brands or for advanced technologies. Most electronics manufacturers, such as Apple, Dell, Canon, Sony, HP, and Samsung, already apply international energy efficiency standards.

Their products are tested by internationally recognised laboratories before they are circulated on the market.

Thus, MoIT revised its decision by Circular 36, allowing enterprises free rein to conduct their own energy labelling. Manufacturers are responsible for the accuracy of the labels on their products and are not limited to sourcing their labelling data from certified domestic testing centres.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Related Contents

Latest News

More News

- Japanese business outlook in Vietnam turns more optimistic (January 28, 2026 | 09:54)

- Foreign leaders extend congratulations to Party General Secretary To Lam (January 25, 2026 | 10:01)

- 14th National Party Congress wraps up with success (January 25, 2026 | 09:49)

- Congratulations from VFF Central Committee's int’l partners to 14th National Party Congress (January 25, 2026 | 09:46)

- 14th Party Central Committee unanimously elects To Lam as General Secretary (January 23, 2026 | 16:22)

- Worldwide congratulations underscore confidence in Vietnam’s 14th Party Congress (January 23, 2026 | 09:02)

- Political parties, organisations, int’l friends send congratulations to 14th National Party Congress (January 22, 2026 | 09:33)

- Press release on second working day of 14th National Party Congress (January 22, 2026 | 09:19)

- 14th National Party Congress: Japanese media highlight Vietnam’s growth targets (January 21, 2026 | 09:46)

- 14th National Party Congress: Driving force for Vietnam to continue renewal, innovation, breakthroughs (January 21, 2026 | 09:42)

Tag:

Tag:

Mobile Version

Mobile Version