Honeywell’s CPS to help Dung Quat refinery improve efficiency

|

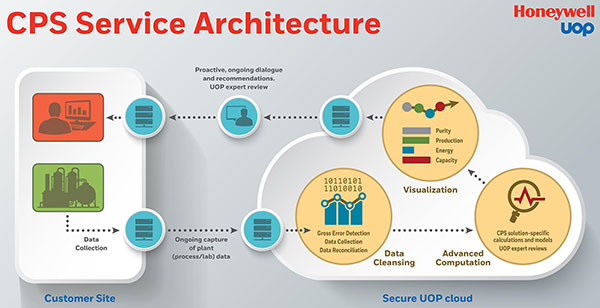

CPS is part of Honeywell’s Connected Plant initiative, which leverages IIoT technologies, services and domain expertise to improve all aspects of industrial operations from supply chain efficiency to asset optimisation.

“Honeywell’s CPS technology uses the plant’s own process data with cloud-based optimisation and reliability solutions to ensure the operation runs at peak efficiency,” said Zak Alzein, vice president for Honeywell UOP’s CPS business. “Honeywell will be in a position to use plant-specific information to provide Binh Son Refining and Petrochemical with actionable recommendations that can significantly improve its profitability.”

CPS gives refineries and petrochemical and gas processing plants greater visibility into their operations. Problems that reduced plant efficiency and productivity and that persistently avoided detection can be quickly identified and resolved using recommendations from CPS. As a result, plants can produce more and avoid unplanned shutdowns for maintenance and repair, resulting in millions of dollars per year in increased productivity.

The service continuously monitors streaming plant data and applies UOP process models and best practices, big data analytics, and machine learning to find latent and emerging performance problems, alert plant personnel and make specific operational recommendations. These recommendations are reported simultaneously to a dedicated Honeywell UOP process advisor, who also monitors performance and provides additional direction and resources.

“The CPS system is an important tool to help our refinery produce more gasoline and consume less energy,” said Tran Ngoc Nguyen, president and CEO of Binh Son Refining and Petrochemical. “We believe it will improve our staff’s capabilities so they can keep our operation running at peak performance.”

The service also can also help manage energy consumption to maintain compliance with regulatory standards, and also bridge knowledge gaps among personnel by leveraging the full breadth of Honeywell UOP’s troubleshooting expertise, available at their fingertips. Taken together, the features of CPS allow refineries to operate more efficiently and make the best use of every barrel of feedstock.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- The generics industry: unlocking new growth drivers (February 04, 2026 | 17:39)

- Vietnam ready to increase purchases of US goods (February 04, 2026 | 15:55)

- Steel industry faces challenges in 2026 (February 03, 2026 | 17:20)

- State corporations poised to drive 2026 growth (February 03, 2026 | 13:58)

- Why high-tech talent will define Vietnam’s growth (February 02, 2026 | 10:47)

- FMCG resilience amid varying storms (February 02, 2026 | 10:00)

- Customs reforms strengthen business confidence, support trade growth (February 01, 2026 | 08:20)

- Vietnam and US to launch sixth trade negotiation round (January 30, 2026 | 15:19)

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

Mobile Version

Mobile Version