ABB drives Vietnam power’s digital era

|

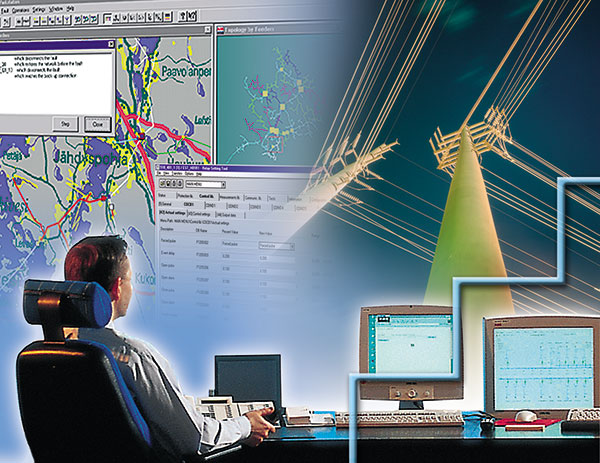

| ABB’s customised solutions help drive efficiency and streamline equipment feedback |

Vietnam now has one of the highest growth rates in the region and in the world. This growth can be attributed to the rising population and the expanding economy.

In order to continue to develop at a sustainable pace, a reliable power supply is needed. The existing power infrastructure cannot easily be replaced. As with any equipment, if it is maintained in a structured way it can perform reliably and last for a long time.

Vietnam has started to upgrade its national grid to meet the requirements of the “smart revolution”. Many substations have had new measurement technologies installed to help with remote monitoring and control. City electrification and mass transportation have led to the increase in electrical power demand, emphasising the need for digitalisation within the national grid.

Vietnam’s energy requirements are driven by the need for a reliable supply to reduce dependence on imported fuels and enable developing rural areas to access affordable electricity.

|

| By cutting response time, supervisors are able to make crucial decisions faster |

Vietnam’s progress towards digitalisation in distribution has already begun:

Phase 1: Completed

- Pilot projects for automatic metering and renewable energy sources are underway.

- Hanoi and Ho Chi Minh City monitoring systems have been upgraded and are ready for “smart grid” operation.

- More than 95 per cent of all substations 110 kilovolts or bigger are automated, ready for smart grid operations.

Phase 2: To 2022

- The country should extend the automatic metering system.

- Commission pilot projects for “smart homes” and “smart cities”.

- Develop technical standards for energy storage and smart appliances.

Phase 3: 2022 onwards

- The progress in expanding information, communication, and technology infrastructure should continue.

- Smart grid applications should be implemented, which will balance supply and demand at the consumer level.

- Use renewable energy in the distribution grid with time-of-use pricing rates.

Sustainability in the power sector

Power sustainability is built on five pillars:

- Efficiency is the key to a sustainable energy future.

- Smart transmission and distribution grids are necessary to support efficiency and renewable energy.

- Integration of renewables and reliability improvements are increasingly important.

- Managing and optimising two-way power flow and information is vital.

- Technology in the form of digitalisation will remain a key factor in addressing market opportunities.

Where ABB Ability comes in

ABB Ability is a unified, cross-industrial digital capability – extending from devices to the cloud – with devices, systems, solutions, services, and a platform that enables customers to access more information and use it to enhance their efficiency. ABB Ability connects customers to the power of the Industrial Internet of Things, and through their services and expertise, they can go further by turning data insights into direct actions that “close the loop” and generate tangible value in the physical world.

ABB tailored digital solutions

Ageing infrastructure, new regulations, distributed energy resources, and the convergence of information technology and operations technology are just a few of the issues that are dramatically changing the utility landscape today.

ABB Ability provides tailored digital solutions and products for the differing needs of utility providers, from power generation to transmission and distribution. Be it advanced diagnostics that prevent unplanned downtime or the complete control of individual coal-fired boilers, ABB Ability grants utility providers an in-depth understanding of their processes and gives them unparalleled control.

Virtual power plants

ABB Ability provides central control and complete optimisation for more than 2,800 distributed units within one of the world’s largest virtually-controlled power plants.

Reliability is a core deliverable for the power industry, which is challenged by the variability of renewable supply, the unpredictability of consumer demand, and, as anyone in Vietnam’s central provinces will tell you, the capricious volatility of Mother Nature. Better modelling – and modelling that improves over time – can have implications not only for service uptime, but also for cost management.

ABB Ability solutions handle real-time processing of large signal and data sets. It manages and controls equipment to insure optimal functionality, regardless of the external scenario.

ABB’s system for utilities lowers the costs for produced energy and optimises internal production. It also improves nominated load schedule fulfilment by enabling utility providers to get power where it is needed, when it is needed.

Power plant boilers

ABB Ability can reduce boiler startup costs by 15 per cent, improve efficiency, and decrease NOx emissions by 5-15 per cent through remote services.

The cost of equipment failure is not measured by downtime alone. The negative monetary effects of faulty equipment are exacerbated by the time and cost of getting the equipment functioning again – as well as the impact of the failure on all processes and outputs both up and down the internal value chain. The figures get particularly expensive when core equipment is involved, so maintaining the performance integrity of the entire system is paramount.

ABB Ability solutions for utilities can remotely monitor a plant and activate a notification mechanism should the performance of a unit falter. This will prompt investigation, analysis, and a subsequent service recommendation. If necessary and available, standby units or other workarounds to maintain the performance integrity of the system will be initiated.

Power plant automation

ABB Ability can help to optimise processes, reduce risk, and increase operator efficiency and plant availability by reducing abnormal events by 40 per cent.

At least 40 per cent of the world’s cyber-attacks target the energy sector, and up to 40 per cent of abnormal events within a given plant are due to operator actions or errors. Maintaining the integrity of the system is therefore an emergent issue that cannot be ignored.

The ABB Ability solution leads to improvements in reliability, availability, forced outage rates, and human resource allocation. Risks are reduced by increasing cyber security, while alarm management results in greater operator efficiency and accident avoidance. Improved control loop performance leads to higher plant availability and efficiency.

Connected equipment lifecycle management

The right work, on the right equipment, at the right time, using the right resources can increase a piece of equipment’s lifespan by three years, save up to 15 per cent in operation and maintenance costs, and reduce overtime costs.

More than ever, utility companies are being challenged to maintain high equipment availability, reliable capacity, and ubiquitous safety, all the while dealing with financial pressures caused by ageing infrastructure and the limited capital available for maintenance and replacements.

ABB Ability Connected Equipment Lifecycle Management ensures that the right work is being done on the right equipment at the right time – driving down maintenance costs, reducing unplanned equipment failures and system outages, and increasing performance, availability, and reliability.

Digital substations

ABB is bringing the Industrial Internet of Things to electrical substations and cutting downtime by up to 50 per cent.

Conventional electrical substations typically use miles of copper cabling for point-to-point connections. Copper is expensive, has limited signalling capacity, and, in the environment of a substation, introduces potential safety risks to workers and equipment.

This outdated method of signalling results in expensive testing and maintenance, leaving critical information stranded until periodic checks are made on location. If supervisors were able to leverage the data in real time, it would be a huge opportunity to improve grid integrity and reduce power interruptions.

By replacing copper wires with fibre-optic connectivity, ABB is able to lay the foundation for automated, high-performance digital substations. Through ABB’s fibre-optic network, they can collect and analyse data using cloud-based software to arrive at solutions that optimise power-grid equipment health.

What the stars mean:

★ Poor ★ ★ Promising ★★★ Good ★★★★ Very good ★★★★★ Exceptional

Latest News

More News

- Digital publishing emerges as key growth driver in Vietnam (January 30, 2026 | 10:59)

- EVN signs key contract for Tri An hydropower expansion (January 30, 2026 | 10:57)

- Vietnam to lead trade growth in ASEAN (January 29, 2026 | 15:08)

- Carlsberg Vietnam delivers Lunar New Year support in central region (January 28, 2026 | 17:19)

- TikTok penalised $35,000 in Vietnam for consumer protection violations (January 28, 2026 | 17:15)

- Digital economy takes centre stage in Vietnam’s new growth model (January 28, 2026 | 11:43)

- EU Council president to visit Vietnam amid partnership upgrade (January 28, 2026 | 11:00)

- Vietnam entering a new growth phase in 2026 (January 28, 2026 | 10:02)

- VIMC targets higher profit and throughput in 2026 (January 26, 2026 | 19:00)

- GEVA a launchpad for Vietnam’s agricultural exports (January 26, 2026 | 12:03)

Mobile Version

Mobile Version